Foam And Pump Together Cement Foaming Machine

Foam And Pump Together Cement Foaming Equipment

- Brand Name:HT

- Type:Foaming Concrete Machine

- Model Number: 100A-102D

- Place of Origin: Henan, China (Mainland)

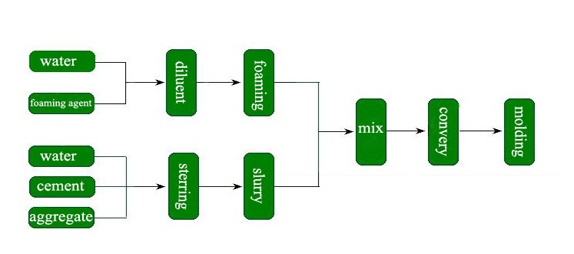

Foam And Pump Together Cement Foaming Equipment:

Application And Features:

1 Fine Structure:

1.1 Machine casing with Taiwan precision sheet metal,car-grade spraying, elegant appearance.

1.2 Machine body is integrately designed, small size, light weight,can use manual forklift to move, or directly welded and fixed to the vehicle to save cost.

2 Advanced Controlling System:

2.1 Master control system uses the most advanced single-chip arithmetic control, each subsystem is modularly designed,easy to upgrade and maintain, high reliability.

2.2 Foaming system uses electronic foaming and frequency conversion metering pumping technology, can accurately control the amount of foaming agent.

2.3 Foaming agent metering adopts frequency conversion metering pump,can accurately control the amount of foaming agent.

2.4 Using the most advanced high-pressure pneumatic pumping system, synchronously achieve big output and high transport height,easy maintenance and low cost.

3 Low Power Consumption:

3.1 Low electricity consumption, the total power is only one fourth of the corresponding hydraulic pump.

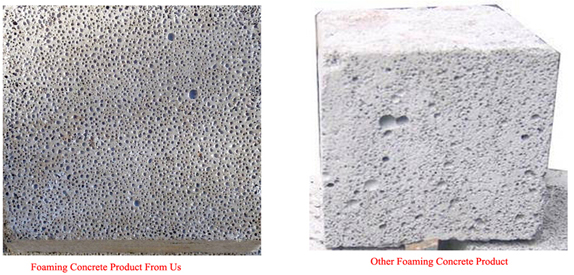

3.2 Compared with other similar devices, our product can save 50-100 kg cement per cubic product, greatly reduce production costs and improve economic efficiency.

4 First Class Operation System:

4.1 Manual and automatic operation, free conversion.

4.2 Digital controlling,the operation is very easy to learn.

4.3 Electrical box with a remote control handle,all functions can be remotely operated.

Technical Parameters Of Different Models:

101A Cement Foaming Equipment:

|

Model |

101A |

|

Voltage |

380 V |

|

Power |

4 KW |

|

Output |

10-12 M3/h |

|

Vertical Conveying Height |

60 M |

|

Level Conveying Distance |

600 M |

|

Particle Size |

≤1.5 CM |

|

Max Pressure |

2.0 Mpa |

|

Outlet pressure |

1.5 Mpa |

|

Dimensions (L * W * H) |

1500*900*900 mm |

|

Weight |

480 Kg |

|

Total Weight |

960 Kg |

102A Foaming Cement Equipment:

|

Model |

102A |

|

Voltage |

380 V |

|

Power |

5.5 KW |

|

output |

15-20 M3/h |

|

Vertical Conveying Height |

100 M |

|

Level Conveying Distance |

600 M |

|

Particle Size |

≤1.5 CM |

|

Max Pressure |

2.0 Mpa |

|

Outlet Pressure |

1.5 Mpa |

|

Dimensions (L * W * H) |

1500*880*1380 mm |

|

Weight |

500 Kg |

|

Total Weight |

980 Kg |

102B Cement Foam Equipment:

|

Model |

102B |

|

Voltage |

380 V |

|

Power |

7.5 KW |

|

output |

25-30 M3/h |

|

Vertical Conveying Height |

120 M |

|

Level Conveying Distance |

1000 M |

|

Particle Size |

≤1.5 CM |

|

Max Pressure |

2.0 Mpa |

|

Outlet Pressure |

1.5 Mpa |

|

Dimensions (L * W * H) |

1700*880*1380 mm |

|

Weight |

600 Kg |

|

Total Weight |

1080 Kg |

102C Foam Cement Equipment:

|

Model |

102C |

|

Voltage |

380 V |

|

Power |

11 KW |

|

output |

50-60 M3/h |

|

Vertical Conveying Height |

80 M |

|

Level Conveying Distance |

800 M |

|

Particle Size |

≤1.5 CM |

|

Max Pressure |

2.0 Mpa |

|

Outlet Pressure |

1.5 Mpa |

|

Dimensions (L * W * H) |

1950*880*1380 mm |

|

Weight |

700 Kg |

|

Total Weight |

1180 Kg |

You can produce different types of bricks/blocks by pouring the foaming concrete to different moulds :

Here are brick moulds:

Here is block mould:

Here is wall mould:

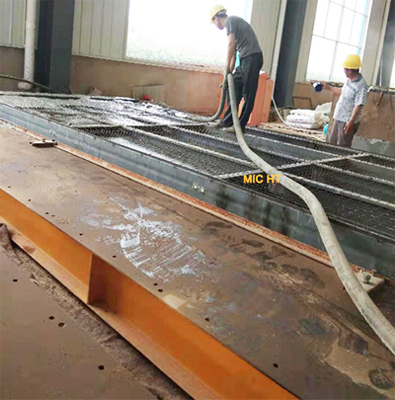

Here is construction for pouring insulation floor layer:

Cement foaming pumping equipment machine:

Cellular lightweight concrete CLC block brick production machine:

Contact Way:

Email: [email protected]

Mobile (Whasapp/Wechat): 008618638556116

Categories

Latest News

Contact Us

Contact: Andy

Phone: 0086 18638556116

Tel: 0086 18638556116

Add: Room 2208, Building B, Zhengshang Huidu Center, Guancheng District, Zhengzhou, Henan, China

andyvictoryy

andyvictoryy  0086 18638556116

0086 18638556116