Curb Pouring Machine--HT400

2022 New Designed Concrete Curb And Gutter Machine

- Brand Name:HT

- Model Number: HT400

- Certification: ISO

- Start-up Mode: Electric Start

Concrete Road Curb And Gutter Machine:

Application And Features:

Compared with the construction of traditional curb stone, the Concrete Curb And Gutter Machine saves the need for pre-setting, transporting to the site and re-installing in place and other processes, reducing the construction cost, improving the construction quality and construction speed. The Concrete Curb And Gutter Machine we produce further improves the function of the existing curb stone slip film machine, meets the construction requirements of different road conditions, and produces various specifications and models of curb stones.

After pre-setting the walking track for the Concrete Curb And Gutter Machine, pouring concrete material can realize the automatic forming and laying of the curb stone. And compared with the original prefabricated molding, manual planing and laying method, it further reduces the manual labor, improves the construction speed, reduces the cost, improves the efficiency, and realizes the continuous molding of curbs. Beautiful linear shape and high strength.

Technical Parameters:

HT400

Specifications

Features

Dimension

2400mmx1700mmx1100mm

Compact, easy to move

Weight

1100kg

Road Kurb Size range

Width≤600mm,height≤450mm

Is Widely applicable for kurbs

Parameters

Of engine set

Fuel

Diesel

Single-cylinder water-cooled diesel engine, simple and reliable

Power

8kw

Output voltage

380v,3 phases

Start-up mode

Electric start

Radiating way

Water cooling

The curbs molding way

Vibrator rod forming

Dry plastic concrete

High strength

Flat vibrator forming

Dry hard concrete

Beautiful appearance

Paving speed

1-4m/min

Imported CVT (Continuously Variable Transmission), facilitate the adjustment of the most suitable paving

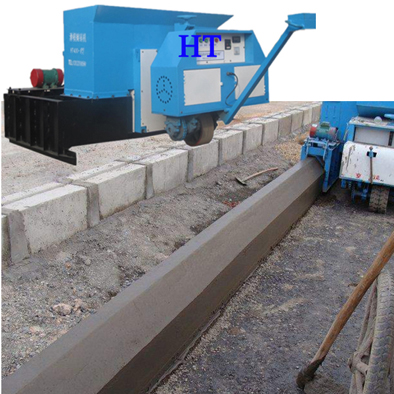

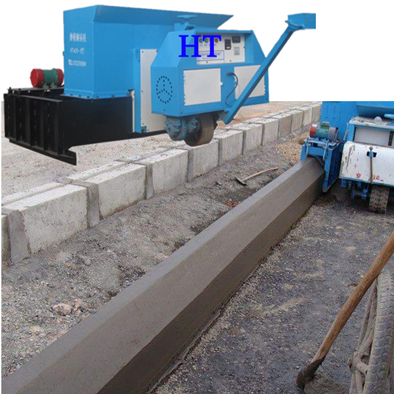

Concrete Curb And Gutter Machine Physical picture:

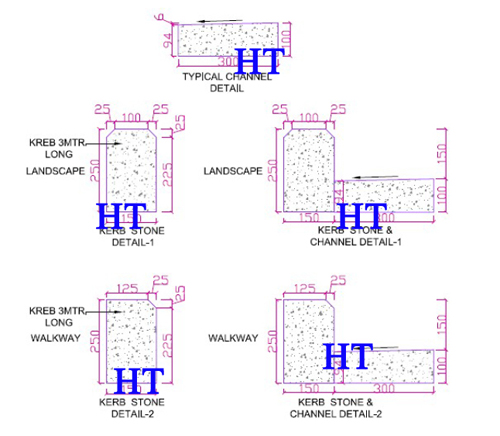

Concrete Curb And Gutter Machine drawing

Concrete Curb And Gutter Machine Packaging diagram :

Categories

Latest News

Contact Us

Contact: Andy

Phone: 0086 18638556116

Tel: 0086 18638556116

Add: Room 2208, Building B, Zhengshang Huidu Center, Guancheng District, Zhengzhou, Henan, China

andyvictoryy

andyvictoryy  0086 18638556116

0086 18638556116